|

|

Post by GTCGreg on Feb 20, 2017 14:37:25 GMT

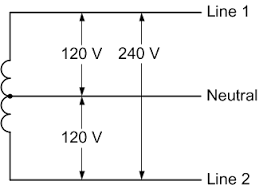

As far as i remember, the US uses a 3 wire/split phase instead of a 3-phase european solution Doesnt that make it four wires? phase 1/2/3 and return/earth?.. What kharnynb is referring to is what we commonly supply to residential homes. It's a three wire, single phase 240 V center tapped system. You get 120 V between the center tap and either leg of the distribution transformer and 240 V going across the entire transformer. There are two types of three phase wiring configuration's used in the United States. A three phase Delta connection only uses three wires and is most often used for powering large three-phase electric motors. The three-phase Y connection is more common and uses four wires. The fourth wire being the neutral. |

|

|

|

Post by the light works on Feb 20, 2017 15:01:49 GMT

As far as i remember, the US uses a 3 wire/split phase instead of a 3-phase european solution Doesnt that make it four wires? phase 1/2/3 and return/earth?.. inside the structure, four are used: A/B phases, grounded conductor (neutral), and grounding/bonding conductor. Bur the service conductors do not have a separate grounding conductor, since everything is bonded at the point of service. this is the load side of a single phase service transformer:  the line side is a single winding tapped from any phase to the grounded conductor. hence, why we call it single phase, even though there are two line conductors. |

|

|

|

Post by the light works on Feb 20, 2017 15:07:41 GMT

Doesnt that make it four wires? phase 1/2/3 and return/earth?.. What kharnynb is referring to is what we commonly supply to residential homes. It's a three wire, single phase 240 V center tapped system. You get 120 V between the center tap and either leg of the distribution transformer and 240 V going across the entire transformer. There are two types of three phase wiring configuration's used in the United States. A three phase Delta connection only uses three wires and is most often used for powering large three-phase electric motors. The three-phase Y connection is more common and uses four wires. The fourth wire being the neutral. a delta service is usually what is referred to as "open delta" which uses one center tapped transformer, and two simple transformers. that way two of the phase conductors can operate at 120V to neutral; while the other "wild" leg is a strange voltage that is pretty much unusable by itself. (and I forget the exact voltage in between working on open delta systems) any two phases on open delta make up 240, which means you have to either have equipment that is designed to not care if it is on a wye system or a delta system, or you have to specifically get 240V equipment. |

|

|

|

Post by the light works on Feb 20, 2017 15:08:57 GMT

note that one of the handy things about our power system is we can import European appliances and simply connect them as 240V appliances.

|

|

|

|

Post by GTCGreg on Feb 20, 2017 15:36:55 GMT

What kharnynb is referring to is what we commonly supply to residential homes. It's a three wire, single phase 240 V center tapped system. You get 120 V between the center tap and either leg of the distribution transformer and 240 V going across the entire transformer. There are two types of three phase wiring configuration's used in the United States. A three phase Delta connection only uses three wires and is most often used for powering large three-phase electric motors. The three-phase Y connection is more common and uses four wires. The fourth wire being the neutral. a delta service is usually what is referred to as "open delta" which uses one center tapped transformer, and two simple transformers. that way two of the phase conductors can operate at 120V to neutral; while the other "wild" leg is a strange voltage that is pretty much unusable by itself. (and I forget the exact voltage in between working on open delta systems) any two phases on open delta make up 240, which means you have to either have equipment that is designed to not care if it is on a wye system or a delta system, or you have to specifically get 240V equipment. Thank you for clarifying that. Over the weekend, I installed the 240 volt outlet (20A) for the CNC router. Now all I have to do is wait for them to deliver something to plug into it. |

|

|

|

Post by the light works on Feb 20, 2017 15:56:15 GMT

a delta service is usually what is referred to as "open delta" which uses one center tapped transformer, and two simple transformers. that way two of the phase conductors can operate at 120V to neutral; while the other "wild" leg is a strange voltage that is pretty much unusable by itself. (and I forget the exact voltage in between working on open delta systems) any two phases on open delta make up 240, which means you have to either have equipment that is designed to not care if it is on a wye system or a delta system, or you have to specifically get 240V equipment. Thank you for clarifying that. Over the weekend, I installed the 240 volt outlet (20A) for the CNC router. Now all I have to do is wait for them to deliver something to plug into it. as the runnign joke goes with out maintenance division: "two weeks." |

|

|

|

Post by kharnynb on Feb 20, 2017 16:42:03 GMT

yea, US is one split phase with a zero, so 3 wires.

Most nordic and central european countries use 3 phase per house with a return and a seperate earth as well for a total of 5 wires "into" the house.

Inside the house there should be a breaker panel that distributes the 3 phases as equal as possible for "average" use to even the phases as much as possible.

Some devices use all 3 phases(over 3 breakers) to create 400V (stoves, sauna heaters etc.) or for high power plugs.

|

|

|

|

Post by kharnynb on Feb 20, 2017 16:45:30 GMT

The US system is cheaper, as it requires only 1 phase per "street" or area, but has higher power balancing issues.

|

|

|

|

Post by GTCGreg on Feb 20, 2017 17:46:33 GMT

The US system is cheaper, as it requires only 1 phase per "street" or area, but has higher power balancing issues. In our neighborhood, one phase feeds my side of the street, the second phase feeds the opposite side of the street, and the third phase feeds the next block. The distribution cycle then repeats. |

|

|

|

Post by the light works on Feb 20, 2017 18:25:41 GMT

The US system is cheaper, as it requires only 1 phase per "street" or area, but has higher power balancing issues. it tends to average out over large areas. where the cheaper comes into play, is it only requires one transformer per "block" of houses. |

|

|

|

Post by kharnynb on Feb 20, 2017 19:05:29 GMT

I guess it depends, in the US you're used to generate more power to make up for the loss of transmission, compared to here, where the infrastructure is more expensive.

|

|

|

|

Post by GTCGreg on Feb 20, 2017 19:30:32 GMT

I guess it depends, in the US you're used to generate more power to make up for the loss of transmission, compared to here, where the infrastructure is more expensive. I don't see where the transmission loses would be any different. The physical infrastructure to distribute split-phase to residential areas may be a little cheaper. |

|

|

|

Post by the light works on Feb 20, 2017 19:43:34 GMT

I guess it depends, in the US you're used to generate more power to make up for the loss of transmission, compared to here, where the infrastructure is more expensive. I don't see where the transmission loses would be any different. The physical infrastructure to distribute split-phase to residential areas may be a little cheaper. true. all our main transmission lines are three phase arrays. it's only rural distribution that drops down to a two-wire system. |

|

|

|

Post by silverdragon on Feb 22, 2017 10:53:58 GMT

Back in hostory, when "electricity" was invented, all local areas had different systems different voltages, and even some had DC instead of AC.

The UK was the world leader in deciding a "National Grid".

Because what you had in one village would not necessarily work in the next village down the valley, we decided to standardise the whole idea of Electricity to ONE set voltage the whole country over, and one "standard" safety plug, we standardised the wiring to one cord-wrapped non bare wiring system, red live black neutral and green or green/yellow stripe as earth.

The earth doesnt leave the house, its grounded into the plumbing that runs underground as well, to supply a safe earthing system for use in emergency, or is fed to a huge spike that is buried down into the earth in each individual house.

"Bloody hell thats a good idea"

The world followed on...

But instead of thinking like they did when it was an Englishman that "standardised" the 4ft6 gauge of railways because it was a good idea and an average of the distance between wheels [at that time] of most road going carts so it was stable as well, the "rest of the world" decided they would not go with a safe working 240volt electrical system, because "we know better"....

Erm... no you dont?.. you know "Different", but not better?..

Some countries still insist that a two wire supply is "safe". Even to the socket and beyond.

It is if you prove that all appliances are double-insulated and tested to make sure you cant get a shock, like anything we allow in a bathroom.

But otherwise, THREE wire with an Earth system built in is a lot safer....

Also when the earth pin is used to slide a plastic cover out of the way inside the socket to prevent people sticking fingers in the holes (kids...) its a lot safer.

We went safety first a long time back on this.

On the 240volt thing?..

[... open to debate, but, historically it was believed...]

240 volt with a lower ampage compared to a 120volt high ampage doing the same job, the 240 volt is going to tingle a bit like trapping your fingers in a door-jam, but wont kill you if you are of average reasonable health.

Thats why its low amp ... its not the volts that kill, its the amps....

Plus, the higher the voltage in transmission over distance, the less percentage of loss due to resistance in the wires?..

As its often some distance from the local generating station transformers to the houses, where we bury the wires underground for safety reasons, they also decided a higher voltage would be more economical, and more efficient.

So being the first to design a working national grid, being the first to set safety standards in place, being the first to design a working national safe electricity system, we were ignored... yet again.. be people around the world who "Know better"....

So excuse me if I jokingly refer to 120volt as "toytown" electricals?.. read on for the reasons...

Most of the stuff we get from europe that is 120volt is "toytown", and yet they demand that we use their safety standards when its proven that our own kite-mark system was of a higher safety standard?.. again, this is why brexit.

Why demand that a country "lower" its standards?.. just so you can flog them cheep shoddy goods?..

Experience has shown this is the case.

Except them bloody germans that is, we have experience that says they are our equals when it comes to quality on a lot of things.

I used to play with 480volt "real mans" industrial motors.

They dont just shock you if you touch the wrong part of the terminal, they throw you out the shed.....

And no I do not believe that 240volt is "better" than 230, 120, 110, or whatever it is where anyone reading this is?..

I just believe we all had different ideas about the how, and too many people were "playing".

Just in the UK, we got ugly early in demanding that there was a set safe standard that didnt send a heart stopping fizz up your left ventricle to "restart" you brain?..

The safety aspect that we put in place, durable plastic plugs with wire clamps and safety guards designed that you didnt touch the terminals by accident, that was what was "Better", and still is better, in my estimation.

Its just that anything that comes with silly safety ideas is usually the low volt 120volt design.

Thats why 120volt is "toytown"

The three phase system was an idea initially to supply each street in the area with a different phase "for safety reasons" so if some navvy with a jack hammer chopped one, the whole area didnt go dark, and where the wires came together, the three phases could be combined to supply the industrial parts with a higher voltage and higher current for the industrial needs.

And also put the street lighting on a different phase to the house electrics, so, again, if some twerp drops his electric shaver in a bath, the whole road didnt descend into darkness. Some street lights were put on 480volt to provide better illumination, to two phase for street lights and one for the housing down each road, hows that?.. and then that got changed so now if my own house suffers a loss of electricity by the failing of one phase, chances are, only one third of the street is affected, because no two houses together are on the same phase, and the street lights are staggered on the same idea.

Only of the whole local generator/transformer fails does the whole area get a blackout.

This also allowed an idea of the possibility of combining two phases to get 480volt in emergency should it be required by tapping in at the base of a lamp-post.

That never got used, nor did it spread about much, because mobile emergency diesel generators became popular.

|

|

|

|

Post by GTCGreg on Feb 22, 2017 14:09:46 GMT

The reason the U.S. and other countries choose 120 Volts is because of Thomas Edison's thick skin. He could touch a 100 volt wire and not receive a shock because of the thick skin on his fingers. He decided that his distribution system would be 100 Volts DC because he felt that was the highest voltage that was safe. Anything above that gave him a shock so he figured it wasn't safe. The truth is that most people can feel a shock at about 60 Volts, but not Edison. Another fact that few people realize is that an AC system that would light an incandescent lamp the same brightness as Edison's 100 Volt DC system would need a peak voltage of 141 Volts. A 220 Volt AC power system actually has a peak voltage of 312 volts.

The idea of 220 volts being safer because it's lower current is flawed. It only takes 100 micro amps, (that's 0.0001 Amps), through your heart to kill you. It's much easier to get that through your heart from a 220 volt source than 120 volts.

An electrical system being isolated from earth ground would be much safer if it wasn't for leakage. They learned early on that not having the electrical system tied to ground was a bad idea but not for the reasons you would think. While an isolated system would still only have 220 (or 120) volts between the two conductors, it could, and usually did, have many thousands of volts between those conductors and earth ground. The reason is because of leakage current from the generators and distribution transformers. It's interesting that in hospital ICUs, where the patients are connected to many pieces of electrical equipment, they use isolated power systems. I have a 1.5kW hospital grade isolation transformer that I use to power any electrical equipment around our swimming pool. I also use it to power the outdoor Christmas decorations to keep them from tripping the GFIC's every time it rains.

|

|

|

|

Post by the light works on Feb 22, 2017 14:39:47 GMT

I now know TWO people who have had to be jump started after contacting a 220V source.

so yeah. 220V safe because of less amps? not quite. as Gary says, even if your lightest fuse carries the number of watts of our lightest 120V circuit (which would make it a 7 amp fuse) it is enough amps to kill a person 14,000 times over. (the figure I work from is half a milliamp). on clean dry skin with a healthy heart, 120V is almost never lethal, because of the resistance of the skin - you'll carry half the amps of a 220V shock.

and yes, 220V feels like closing a door on your fingers. 277 feels like getting hit with a hammer. 120V feels like after your hand goes to sleep, only it quits when you let go.

the reason why hospitals use isolated supply is because the way the earth ground works to prevent you getting shocked is that if something goes wrong, it attempts to carry enough current to trip the breaker. equipotential bonding, which the earth ground also does in average situations, strives to make every conductive thing default to the same voltage. - around a pool, EVERY conductive thing except the tiny bits of metal you are carrying around, is required to be bonded to the equipotential grid. this is because wet skin, especially wet skin soaked in chemical laden water, is much more conductive than clean dry skin. and it has happened that a person with his toe against a metal water fitting has touched a metal handrail, and been lit up like a christmas tree.

|

|

|

|

Post by GTCGreg on Feb 22, 2017 14:51:07 GMT

- around a pool, EVERY conductive thing except the tiny bits of metal you are carrying around, is required to be bonded to the equipotential grid. this is because wet skin, especially wet skin soaked in chemical laden water, is much more conductive than clean dry skin. and it has happened that a person with his toe against a metal water fitting has touched a metal handrail, and been lit up like a christmas tree. Right. When they installed our pool, they tied the slide legs, hand rail, ladder, underwater light housing, and even the rebar in the concrete to a single 8' ground rod. It was the one thing that the building inspector paid real close attention to checking. |

|

|

|

Post by the light works on Feb 22, 2017 15:11:15 GMT

- around a pool, EVERY conductive thing except the tiny bits of metal you are carrying around, is required to be bonded to the equipotential grid. this is because wet skin, especially wet skin soaked in chemical laden water, is much more conductive than clean dry skin. and it has happened that a person with his toe against a metal water fitting has touched a metal handrail, and been lit up like a christmas tree. Right. When they installed our pool, they tied the slide legs, hand rail, ladder, underwater light housing, and even the rebar in the concrete to a single 8' ground rod. It was the one thing that the building inspector paid real close attention to checking. it is a little comical. a wet niche light has #14 supply wires and a #8 ground wire. |

|

|

|

Post by silverdragon on Feb 23, 2017 9:06:59 GMT

The idea of 220 volts being safer because it's lower current is flawed. It only takes 100 micro amps, (that's 0.0001 Amps), through your heart to kill you. It's much easier to get that through your heart from a 220 volt source than 120 volts. Yes I knew which is why I added the caveat "At that time" [... open to debate, but, historically it was believed...] bit before I said that?.. there is a very small change that if applied in the right place will stop the heart, and re-start it, which is how pacemakers work, and they have very tiny batteries?.. You should see the contact-less motor that powers my main Pond pump... just how the hell does that work with no brushes on the rotor?.. well, that amused me for an hour before I duk-fu'd the answer and took a lesson in Magnetic force and contact-less motors, and the amazement that I am feeding 240volt straight into my pond. Yes the wire is 240 volt, yes its underwater, yes of course its proofed to be 100% waterproof for many years and fail-safe as long as it is inspected regularly for any sign of damage, and yes it has its own sensors on the casing that if they sense any leakage in the water the pump "Trips", and thats on micro-voltage micro-amp-age leeks. Expensive?. Well, you can pick up a pond pump like that that deals in less than 100 gallons a min for under £100 these days, but mine does 1,000 gallons per hour minimum, I will leave that to you to duckfu if you want, I dont want to know, the price of replacement would scare me right now.... I now know TWO people who have had to be jump started after contacting a 220V source. If that didnt include me, you now know three. Well, ok, it was 240 volt at that time, but I took a blue arm and a bang on the chest by the first aider one time back in college when a rouge transformer blew me off the desk.... quote]the reason why hospitals use isolated supply is because the way the earth ground works to prevent you getting shocked is that if something goes wrong, it attempts to carry enough current to trip the breaker. equipotential bonding, which the earth ground also does in average situations, strives to make every conductive thing default to the same voltage. - around a pool, EVERY conductive thing except the tiny bits of metal you are carrying around, is required to be bonded to the equipotential grid. this is because wet skin, especially wet skin soaked in chemical laden water, is much more conductive than clean dry skin. and it has happened that a person with his toe against a metal water fitting has touched a metal handrail, and been lit up like a christmas tree.[/quote] Hospitals also have a lot of expensive monitoring equipment on this "bag of water" the last time I blew one of my own fuses and ended up there, if a stray spark to ground had hit that lot, I suspect at least half a million in replacement costs?.. Therefore, Hospital equipment has very sensitive MCB's on almost everything and is double-triple isolated to ensure zero leakage. Plus, you wanna see what goes on in isolating a MRI scanner... you aint even allowed a wristwatch anywhere near one?.. even the floors are made up of that shock resistant mat you get on test benches. There is a healthy paranoia that goes on in electricals in hospitals. I say for good reasons as well. Right. When they installed our pool, they tied the slide legs, hand rail, ladder, underwater light housing, and even the rebar in the concrete to a single 8' ground rod. It was the one thing that the building inspector paid real close attention to checking. I have a large copper strip, ex 20mil grounding wire, from inside the pond to up over the top and down to buried underneath the pond as a "earth" . There is nothing at all metal from water to four foot foot above the pond. The "roof" that holds a shade-sail and netting up [predator prevention..] above that is bonded to the metal poles that go down 8ft below the bottom of the pond that hold up the side walls, that protrude three foot above ground level, [so thats about 16 ft length] they are aluminium, and very strong, "scaffolding bar" build, and at some point also touch that earth wire from inside the pond. Ponding those poles down 12ft into earth took some going..... a week just to get that far. "I have been told" I am "almost" 100% proof against a possible lightning strike?.. I dont believe that, so I have a lightning pole elsewhere on the property to ensure that attracts the strike "should it happen", I dont want to have to replace all those fish.... Pond lighting, I have "light boxes" that have a light source above water and isolated that use mirrors to take the light below water level, a sort of inverted periscope idea, it works well, and lets you NOT use underwater lighting. Underwater lighting during summer also heats the pond too much.... thats why they are above water?. You ever seen a fish sweat?.. I have a system that cools the water as needed, the fish find that outflow on hotter days, and use that shade sail shadow to hide from direct sun. |

|

|

|

Post by the light works on Feb 23, 2017 14:47:14 GMT

there are other reasons to disallow all watches around the MRI machine. a person I knew worked in security back in the days of tape storage, and they had a no watches policy around the bulk tape eraser. she forgot one day, and it did interesting things to the watch.

hospitals are in an interesting situation - their patients are usually not as robust as the average person, so a shock is more likely to be fatal - but loss of power to a piece of equipment is also more likely to be fatal. so they play a juggling game to try to make the system as idiot resistant as humanly possible. in our standard installation, the ground pin of the receptacle is at the bottom. it isn't mandatory - just custom. one inspector once told me that the theory was that if the weight of the cord pulls the plug out, the ground pin will be the last to break contact. in hospitals, it is mandatory to have the ground pin at the top - the official reasoning is that if something drops down and hits the plug, there is one last chance that it will hit the ground pin and bounce to the "safe" side, whereas if the plug is partially out, and it slides down against the blades, it will probably hit the hot blade cause a short.

|

|