|

|

Post by c64 on Nov 29, 2015 16:17:39 GMT

In the 230V/400V part of the world, a standard "big motor" looks like this:  The box on top is for wiring it up. You can run it 3~ in star configuration, 3~ triangle or mixed mode (star to spin up, triangle to run), 1~ with Steinmetz capacitor sitting next to the box or inside the switchboard cabinet, 1~ with miniature capacitor inside the box (simple to replace) or with a frequency converter. |

|

|

|

Home HVAC

Nov 29, 2015 16:25:08 GMT

via mobile

Post by GTCGreg on Nov 29, 2015 16:25:08 GMT

In the 230V/400V part of the world, a standard "big motor" looks like this:  The box on top is for wiring it up. You can run it 3~ in star configuration, 3~ triangle or mixed mode (star to spin up, triangle to run), 1~ with Steinmetz capacitor sitting next to the box or inside the switchboard cabinet, 1~ with miniature capacitor inside the box (simple to replace) or with a frequency converter. A friend of mine was a carpenter turned electrician in a mill working woodshop. The dust extractor motor went bad and he replaced it. He called me to ask if I could take a look because while the thing appeared to be running it wasn't sucking out any dust. Sure enough, it was a three-phase motor and he had reversed two of the phases. The fan was running, it was just turning backwards. |

|

|

|

Post by the light works on Nov 29, 2015 16:33:47 GMT

our big motors are preferable three phase. Attachment Deletedthese have a total of six windings - they can be connected to 120/208V wye, open delta 120/240, 277/480. or 480V delta power. you COULD hook them up in a wye configuration, but why waste the lead. most of our three phase motors are delta connected, because it is more convenient. you don't need a nuke on a delta motor connection. edit: most of our modern three phase power systems are wye connected - older industrial plants are open delta, because you can build it with only two transformers; and industrial facilities don't need much 120V. |

|

|

|

Post by c64 on Nov 29, 2015 17:09:21 GMT

our big motors are preferable three phase. View Attachmentthese have a total of six windings - they can be connected to 120/208V wye, open delta 120/240, 277/480. or 480V delta power. you COULD hook them up in a wye configuration, but why waste the lead. most of our three phase motors are delta connected, because it is more convenient. you don't need a nuke on a delta motor connection. edit: most of our modern three phase power systems are wye connected - older industrial plants are open delta, because you can build it with only two transformers; and industrial facilities don't need much 120V. Over here, we don't need transformers inside the buildings except for special power supply (very high current and/or different voltages). Each house is provided with 3~ 230V so you can have 230V single phase, 230V rotary and 400V rotary. |

|

|

|

Post by the light works on Nov 30, 2015 1:31:25 GMT

our big motors are preferable three phase. View Attachmentthese have a total of six windings - they can be connected to 120/208V wye, open delta 120/240, 277/480. or 480V delta power. you COULD hook them up in a wye configuration, but why waste the lead. most of our three phase motors are delta connected, because it is more convenient. you don't need a nuke on a delta motor connection. edit: most of our modern three phase power systems are wye connected - older industrial plants are open delta, because you can build it with only two transformers; and industrial facilities don't need much 120V. Over here, we don't need transformers inside the buildings except for special power supply (very high current and/or different voltages). Each house is provided with 3~ 230V so you can have 230V single phase, 230V rotary and 400V rotary. other than big commercial that runs the lights and ACs on 277/480 and the rest of the building on 120/208, we don't have transformers inside the building either. residential loads run 120/240 single phase; though most residential high power appliances can now run on anything from 208-240, because that lets big apartment complexes run three phase services |

|

|

|

Post by GTCGreg on Nov 30, 2015 1:55:48 GMT

our big motors are preferable three phase. View Attachmentthese have a total of six windings - they can be connected to 120/208V wye, open delta 120/240, 277/480. or 480V delta power. you COULD hook them up in a wye configuration, but why waste the lead. most of our three phase motors are delta connected, because it is more convenient. you don't need a nuke on a delta motor connection. edit: most of our modern three phase power systems are wye connected - older industrial plants are open delta, because you can build it with only two transformers; and industrial facilities don't need much 120V. I had to wire up a motor like that for a conveyor system once. It had 12 wires coming out of it and none were or labeled. After about 4 hours of trial and error, a lot of growling and a little smoke, I finally got it to work. To complicated things a little further, it had to be reversible. |

|

|

|

Post by the light works on Nov 30, 2015 4:05:01 GMT

our big motors are preferable three phase. View Attachmentthese have a total of six windings - they can be connected to 120/208V wye, open delta 120/240, 277/480. or 480V delta power. you COULD hook them up in a wye configuration, but why waste the lead. most of our three phase motors are delta connected, because it is more convenient. you don't need a nuke on a delta motor connection. edit: most of our modern three phase power systems are wye connected - older industrial plants are open delta, because you can build it with only two transformers; and industrial facilities don't need much 120V. I had to wire up a motor like that for a conveyor system once. It had 12 wires coming out of it and none were or labeled. After about 4 hours of trial and error, a lot of growling and a little smoke, I finally got it to work. To complicated things a little further, it had to be reversible. oh, god. who obscures the markings on a heavy motor... I guess I should have said they have a multiple of 6 windings. I forget whether they are 3600 RPM or if they are slower. |

|

|

|

Post by c64 on Nov 30, 2015 17:32:53 GMT

Over here, we don't need transformers inside the buildings except for special power supply (very high current and/or different voltages). Each house is provided with 3~ 230V so you can have 230V single phase, 230V rotary and 400V rotary. we don't have transformers inside the building either. But very close to the buildings. With 230V/400V rotary current systems, the distance between transformer and building can be much greater. One of those is usually enough for medium sized village:  They used to look like this until the 1970s:  |

|

|

|

Post by GTCGreg on Nov 30, 2015 18:05:44 GMT

The transformers used in residential areas usually look like this. There is one behind my house that is fed from a 7,200 volt single phase feeder. The output of the transformer is 120/240 volts and supplies power to 6 to 12 houses.  The transformers for commercial building look more like this. They are usually pretty close to the building and are usually 12.1 KV 3 phase to 480/277 volts 3 phase. These are usually oil cooled. Often there are smaller dry transformers inside the building that knock down the 480 volts to 120/240. The 480 is used for the large power systems such as elevators and HVAC while 277 is used for general lighting. The 120 is the standard line voltage in the U.S. for smaller appliances such as computers, coffee makers etc.  Of course, sometimes we just hang them from sticks stuck in the ground.  |

|

|

|

Post by c64 on Nov 30, 2015 18:16:39 GMT

There is one behind my house that is fed from a 7,200 volt single phase feeder. The output of the transformer is 120/240 volts and supplies power to 6 to 12 houses. In Germany, there are about 600.000 transformer stations transforming "middle voltage" (1kV..52kV) to "low voltage" (230V/400V) feeding 40.4 million households. |

|

|

|

Post by the light works on Nov 30, 2015 18:25:44 GMT

here is a picture showing our overhead power distribution setup - except where I am, the phase conductor is always highest on the pole and the transmission neutral is below the transformer - basic rule is higher on the pole is higher voltage. if there were overhead TV and telephone, they would be beneath the power. but note how much less metal is used to bring the 7000V primary into the pole compared to the wire used to feed the two houses. the power company will size the transformers to feed the loads each transformer serves, with each transformer usually serving about a 200' radius. maybe 6 or 7 taps per transformer at the most. this also limits the available fault current to around 100,000 amps, letting us use much lighter switchgear for the service disconnect.  |

|

|

|

Post by c64 on Nov 30, 2015 18:32:13 GMT

here is a picture showing our overhead power distribution setup - except where I am, the phase conductor is always highest on the pole and the transmission neutral is below the transformer - basic rule is higher on the pole is higher voltage. if there were overhead TV and telephone, they would be beneath the power. but note how much less metal is used to bring the 7000V primary into the pole compared to the wire used to feed the two houses. the power company will size the transformers to feed the loads each transformer serves, with each transformer usually serving about a 200' radius. maybe 6 or 7 taps per transformer at the most. this also limits the available fault current to around 100,000 amps, letting us use much lighter switchgear for the service disconnect. Our switchgear is just a fireproof glove. You open the door to a transformer house, walk in, put on the glove and throw the lever. For the modern ones, the lever is far away from the actual switch so you can do it with bare hands. Same for the cabinets replacing the brick houses. |

|

|

|

Post by c64 on Nov 30, 2015 18:40:03 GMT

To reduce the amount of transformers more, we use higher currents as well.

Here is a nice video what happens if there is a bolt not tightened in a "current rail" carrying 1kA. And the transformer in my area is 3x 50kA!

The second test simulates what will happen to the cabinet cover of a 3kA system with something causing a short behind the cover.

|

|

|

|

Post by the light works on Nov 30, 2015 18:40:41 GMT

here is a picture showing our overhead power distribution setup - except where I am, the phase conductor is always highest on the pole and the transmission neutral is below the transformer - basic rule is higher on the pole is higher voltage. if there were overhead TV and telephone, they would be beneath the power. but note how much less metal is used to bring the 7000V primary into the pole compared to the wire used to feed the two houses. the power company will size the transformers to feed the loads each transformer serves, with each transformer usually serving about a 200' radius. maybe 6 or 7 taps per transformer at the most. this also limits the available fault current to around 100,000 amps, letting us use much lighter switchgear for the service disconnect. Our switchgear is just a fireproof glove. You open the door to a transformer house, walk in, put on the glove and throw the lever. For the modern ones, the lever is far away from the actual switch so you can do it with bare hands. Same for the cabinets replacing the brick houses. you mean you have to run to the central transformer and black out the entire town if you get a high amperage fault in a house? if I have a major fault, my main breaker will trip - and if that fails, the pole top fuse will blow. |

|

|

|

Post by the light works on Nov 30, 2015 18:44:50 GMT

To reduce the amount of transformers more, we use higher currents as well. Here is a nice video what happens if there is a bolt not tightened in a "current rail" carrying 1kA. And the transformer in my area is 3x 50kA! The second test simulates what will happen to the cabinet cover with a loose bolt in the current rail behind it. in comparison, the average residential service transformer in the US is protected by a 5-25A fuse. |

|

|

|

Post by the light works on Nov 30, 2015 18:50:52 GMT

and here's a major fault, here.

you have to get into the extra high voltage lines to get a major explosion, here.

|

|

|

|

Post by c64 on Nov 30, 2015 18:52:47 GMT

Our switchgear is just a fireproof glove. You open the door to a transformer house, walk in, put on the glove and throw the lever. For the modern ones, the lever is far away from the actual switch so you can do it with bare hands. Same for the cabinets replacing the brick houses. you mean you have to run to the central transformer and black out the entire town if you get a high amperage fault in a house? if I have a major fault, my main breaker will trip - and if that fails, the pole top fuse will blow. Or just toss a trailer into the nearby distributor cabinet: Here is a video of the glove, you pull out the main fuses of the building: And this is the modern system:  You pull the lever which first disconnects the fuses and then opens the lid where you can pick up the fuses with bare hands. |

|

|

|

Post by c64 on Nov 30, 2015 18:56:32 GMT

and here's a major fault, here. you have to get into the extra high voltage lines to get a major explosion, here. A piece of aluminium foil tossed into a common house "Panzersicherungskasten" (armoured fuse box) will do nicely: Common cloth will catch fire, the arcs are way hotter than the surface of the sun! |

|

|

|

Post by the light works on Nov 30, 2015 19:02:42 GMT

here, we just turn the main breaker off. when we are ready to re energize, we just turn it back on. mine looks like this.  |

|

|

|

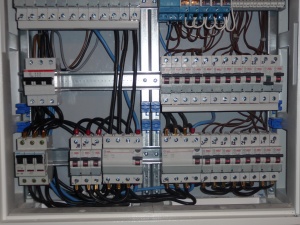

Post by c64 on Nov 30, 2015 19:19:49 GMT

I managed to find a neat video in English: The 9000°C is not the arc itself, the blowout reaches this temperature, the air and stuff blowing out of the box. When inhaling this, you die 20 minutes later from burned lungs. This is the weird part, everything wasn't that bad until the ambulance arrives (3..5 min), then the burned lung starts to fail and there is nothing anybody could do about it. Your "main breaker" looks like what I have for my stove.  In the basement, there is the "armoured fuse box", usually 3x100A for an ordinary house. Then there is a cabinet with the meter and the circuit breakers. Or just the meter and "pre-fuses", usually the NEOZED kind". Then each flat has a circuit breaker box like in the picture above. Neozed:  So to handle outlets and lights, you simply switch off the breakers. If you want to work on the breakers, you remove the pre-fuses. If you don't have them, there usually is an extra main breaker or the power company can remove the "armoured fuses" or pop out the meter which also disconnects the power. Also they can dig up the cable under the sidewalk and disconnect the house using special tools on the life underground wiring. |

|