|

|

Post by silverdragon on Mar 14, 2015 9:31:43 GMT

Damascus steel....

We have some, we know what it is, its definitely true stuff, but, we dont know how they made it.

Search of internet is not giving me any solid proof of how it was made.

Anyone here have any idea?...

I think I may have hit overload on my research, even Firefox is complaining about too many open tabs on this subject.

Does Adam know anything?...

After all, he does have a spare sword forge hanging about.

Just how did the make the stuff.

|

|

|

|

Post by the light works on Mar 14, 2015 14:09:03 GMT

Damascus steel.... We have some, we know what it is, its definitely true stuff, but, we dont know how they made it. Search of internet is not giving me any solid proof of how it was made. Anyone here have any idea?... I think I may have hit overload on my research, even Firefox is complaining about too many open tabs on this subject. Does Adam know anything?... After all, he does have a spare sword forge hanging about. Just how did the make the stuff. I know multiple methods. at least academically. the basics of it are you have high carbon steel and low carbon steel and you fold them together like making pastry. traditionally, they would take billets of too hard and too soft steel, and use the forge to weld them together, and then hammer the billet out and fold it over until the layers were thin, but not completely homogenous. a lot of modern damascus steel smiths use steel cable, which means they only hammer it enough to weld the strands together, and then form their blank. I have watched both of those methods, and even been a hammer monkey for one smith. |

|

|

|

Post by Cybermortis on Mar 14, 2015 21:00:48 GMT

Do correct me if I'm wrong. But I thought that there was actually two types of Damascus steel.

The original steel got its reputation due to being produced from a specific type of ore. While the later type was actually just a method of folding two different types of steel (or steel and iron, I forget). The latter folding technique isn't/wasn't all that unique as both the Japanese and Vikings did something very similar.

|

|

|

|

Post by silverdragon on Mar 15, 2015 9:18:19 GMT

The question is how did they do that, long before anyone else had managed steel properly.

Its the getting it "thin" enough to fold over, roll up into cylinders, make steel wires out of, and make into blades, whilst the rest of the world was still arguing over [what shape a wheel should be]. or something like that.

|

|

|

|

Post by the light works on Mar 15, 2015 14:39:28 GMT

Do correct me if I'm wrong. But I thought that there was actually two types of Damascus steel. The original steel got its reputation due to being produced from a specific type of ore. While the later type was actually just a method of folding two different types of steel (or steel and iron, I forget). The latter folding technique isn't/wasn't all that unique as both the Japanese and Vikings did something very similar. It is called "Damascus" steel, because steelworkers in Damascus were the first in the western world to develop that level of workmanship. I would not be surprised if, considering steelworking was still a very new art, and alloying was unheard of, the ore used in Damascus produced a better grade of steel, as well. the other thing to keep in mind is that modern steel alloys are superior to damascus steel when the alloy is properly selected for the purpose it is to be used for. |

|

|

|

Post by silverdragon on Mar 16, 2015 8:33:51 GMT

I would hope that modern steel is a lot better, its computer controlled to make sure the amount of carbon is "just right"

Side note, I have only just found out, how steel is made, and how that is different from Iron.

Its the amount of carbon in the steel.

Thats all.

Dont know why, but I had always thought it was some kind of alloy before now?...

<Duh>.....I suppose it is, its Iron and Carbon, Fe plus C....thats an alloy in anyone elses books innit?...

|

|

|

|

Post by Cybermortis on Mar 16, 2015 14:00:04 GMT

Actually Dragon you were not that far off the mark. Most steels are alloys as they contain other metals in some quantity. This gives them qualities basic steel doesn't have, such as resistance to rust or staining. If, for example, you handle the blade of a traditional sword and forget to clean it you will end up marking the blade with your fingerprints permanently. You don't have to worry about that with modern steel kitchen knives, which use stainless steel.

|

|

|

|

Post by rick4070 on Apr 30, 2015 23:27:58 GMT

|

|

|

|

Post by silverdragon on May 1, 2015 6:19:53 GMT

Hello Rick, you been busy?.. we dont get to see you a lot....

Thanks for the article, its educational into how the steel manages to be so tough and do flexible at the same time.

The thing is, just how did they come up with that in the first place.

I get the idea here that its more of a evolution by natural selection thing...

That someone tried it, and it worked, and because it worked so well, it got a name for it, and that made it desirable.

So just HOW did they get the ability back then to go that technical?...

Its certainly something we can all do today without too much hardware involved...

But the hardware we would use today, it just wasnt available back then?...

Heck from what I can find out, getting Steel was "pot luck"

You heated the crucible pot 'till it glowed a certain colour for a certain time, then broke it open, and hoped the glowing hunk of molten metal had enough of the right stuff to make it steel and not just Iron.

Even from that site, they are open to suggestion...?...

I Want it Back......

However, the best guess anyone can come up with is "Happy accident".

The fact that the iron ore from that part of the world had the right impurities, that it was first forged into long thing wire, the repeatedly folded and woven into a long ingot, that was further processed into a blank, then a blade.

Someone got "OCD" about making the blades, thats for certain, and they worked at it for a long time.

But was that all just by accident, or, did someone there know what they were doing, and did it all happen by design, first knowing how much impurities they needed, or even adding impurities in the form of raw carbon or charcoal into the iron to get the right mix...

And how did they know?...

|

|

|

|

Post by silverdragon on May 1, 2015 6:32:48 GMT

Personal addition.

At one point in family history, one of our members was a Master Armourer.

The only FULL time master armourer in England.

His work is seen in the Jorvik centre in York, as he "reproduced" some of the blades and armour using the

historically correct procedures available at that time to make items for display.

Some of that was unfortunately lost in the floods a few years back....

He also made reproduction armour and swords for collectors, and made light restorations of broken stuff.

All to historically correct methods.

He fascinated me.

I spent some time with him producing my own blade....

Which is NOT a display thing, and is carefully secured away.

I am not surprised that it took me a long time.

To say those things are heavily manual labour intensive is an understatement.

For reference, I have a simple letter opener on my desk which has a forged rams head handle...

That alone took me two days to produce, with his help, and its only 5 inch long, it certainly isnt any art work.

It was the practise piece to teach me the methods I would need.

At the end of the two weeks, I was a physical wreck....

Thats why most blacksmiths are pictured as well muscled guys who can snap trees in half by leaning on them...

|

|

|

|

Post by Cybermortis on May 1, 2015 11:58:16 GMT

It is also why Swords were expensive items, which in turn is also one of the reasons those who had swords usually picked other weapons to do their fighting with.

|

|

|

|

Post by the light works on May 2, 2015 5:15:22 GMT

It is also why Swords were expensive items, which in turn is also one of the reasons those who had swords usually picked other weapons to do their fighting with. swords were for dueling, maces were for war. |

|

|

|

Post by c64 on Aug 16, 2015 14:30:44 GMT

First of all, you need the correct material. Modern Damascus knifes are made from old Russian tank gun barrels since they have the correct material properties.

Then the metal is folded several times. Every time the metal is put into the oven to reheat, it is exposed to the fumes of the coal fire so the surface starts to gain carbon. You need a special oven and need to reheat the metal for the correct time. Then by folding, you put one of the surfaces into the center of the metal lump. This is how the many alternating layers of hard and soft steel are made.

This method was discovered by accident. When you make an mistake shaping the blade, you fold the blade back into a lump again, reheat and start all over. And then it had turned out that blades which were remade over and over again (due to incompetence of scholars) are actually much more durable. So they started to refold the lump of metal on intention several times before actually attempting to shape the blade.

|

|

|

|

Post by the light works on Aug 16, 2015 14:55:58 GMT

one thing a swordsmith taught me is that the myth that Japanese smiths folded the blade of a katana one thousand times, is false - it was actually folded to a thousand layers - which is around seven folds. (remember the episode about folding paper multiple times?)

|

|

|

|

Post by c64 on Aug 16, 2015 15:12:23 GMT

one thing a swordsmith taught me is that the myth that Japanese smiths folded the blade of a katana one thousand times, is false - it was actually folded to a thousand layers - which is around seven folds. (remember the episode about folding paper multiple times?) They usually fold it between 4 and 10 times. The more you fold, the greater the risk that it turns bad. A good one is folded at least 6 times, 8 times is very good. There is a difference between folding a sword and folding paper. You can't stretch paper but you can stretch hot metal. Also you can't unfold the sword since it is fused and the folded edge breaks up. This is like cutting a paper in two and gluing the sheets together again and this you can do more than 7 times easily. |

|

|

|

Post by the light works on Aug 16, 2015 15:50:53 GMT

one thing a swordsmith taught me is that the myth that Japanese smiths folded the blade of a katana one thousand times, is false - it was actually folded to a thousand layers - which is around seven folds. (remember the episode about folding paper multiple times?) They usually fold it between 4 and 10 times. The more you fold, the greater the risk that it turns bad. A good one is folded at least 6 times, 8 times is very good. There is a difference between folding a sword and folding paper. You can't stretch paper but you can stretch hot metal. Also you can't unfold the sword since it is fused and the folded edge breaks up. This is like cutting a paper in two and gluing the sheets together again and this you can do more than 7 times easily. but the exponential increase in the number of layers remains the same. - and what happens if you fold it too many times is it mixes instead of layering so instead of having folded steel you have a steel alloy. |

|

|

|

Post by c64 on Aug 16, 2015 16:51:29 GMT

They usually fold it between 4 and 10 times. The more you fold, the greater the risk that it turns bad. A good one is folded at least 6 times, 8 times is very good. There is a difference between folding a sword and folding paper. You can't stretch paper but you can stretch hot metal. Also you can't unfold the sword since it is fused and the folded edge breaks up. This is like cutting a paper in two and gluing the sheets together again and this you can do more than 7 times easily. but the exponential increase in the number of layers remains the same. - and what happens if you fold it too many times is it mixes instead of layering so instead of having folded steel you have a steel alloy. Not quite. YOu start with one layer, after heating you get 3. When you fold, one surface blends into a single layer so you get 5 instead of 6. You always get one layer less. And you get wrinkles in the layer far faster than the layers blend into each other. Wrinkles create a plywood effect, it prevents that you can bend the blade as intended so it breaks earlier. The more accurate you work, the more layers you can create improving the blade. That's why a modern Damascus knife can have more layers than a classic one crafted without modern machinery. |

|

|

|

Post by the light works on Aug 16, 2015 22:13:27 GMT

but the exponential increase in the number of layers remains the same. - and what happens if you fold it too many times is it mixes instead of layering so instead of having folded steel you have a steel alloy. Not quite. YOu start with one layer, after heating you get 3. When you fold, one surface blends into a single layer so you get 5 instead of 6. You always get one layer less. And you get wrinkles in the layer far faster than the layers blend into each other. Wrinkles create a plywood effect, it prevents that you can bend the blade as intended so it breaks earlier. The more accurate you work, the more layers you can create improving the blade. That's why a modern Damascus knife can have more layers than a classic one crafted without modern machinery. the modern folded damascus i have seen starts with 7 layers. the point is that it is not start with one layer and fold it to get two, fold again to get three, fold it again to get four. assuming you are calling the carbon coating layers, you take a layer, heat to get three, fold to get five, heat to get 7, fold to get 13, heat to get 15, fold to get 29, etc. |

|

|

|

Post by silverdragon on Aug 18, 2015 9:02:44 GMT

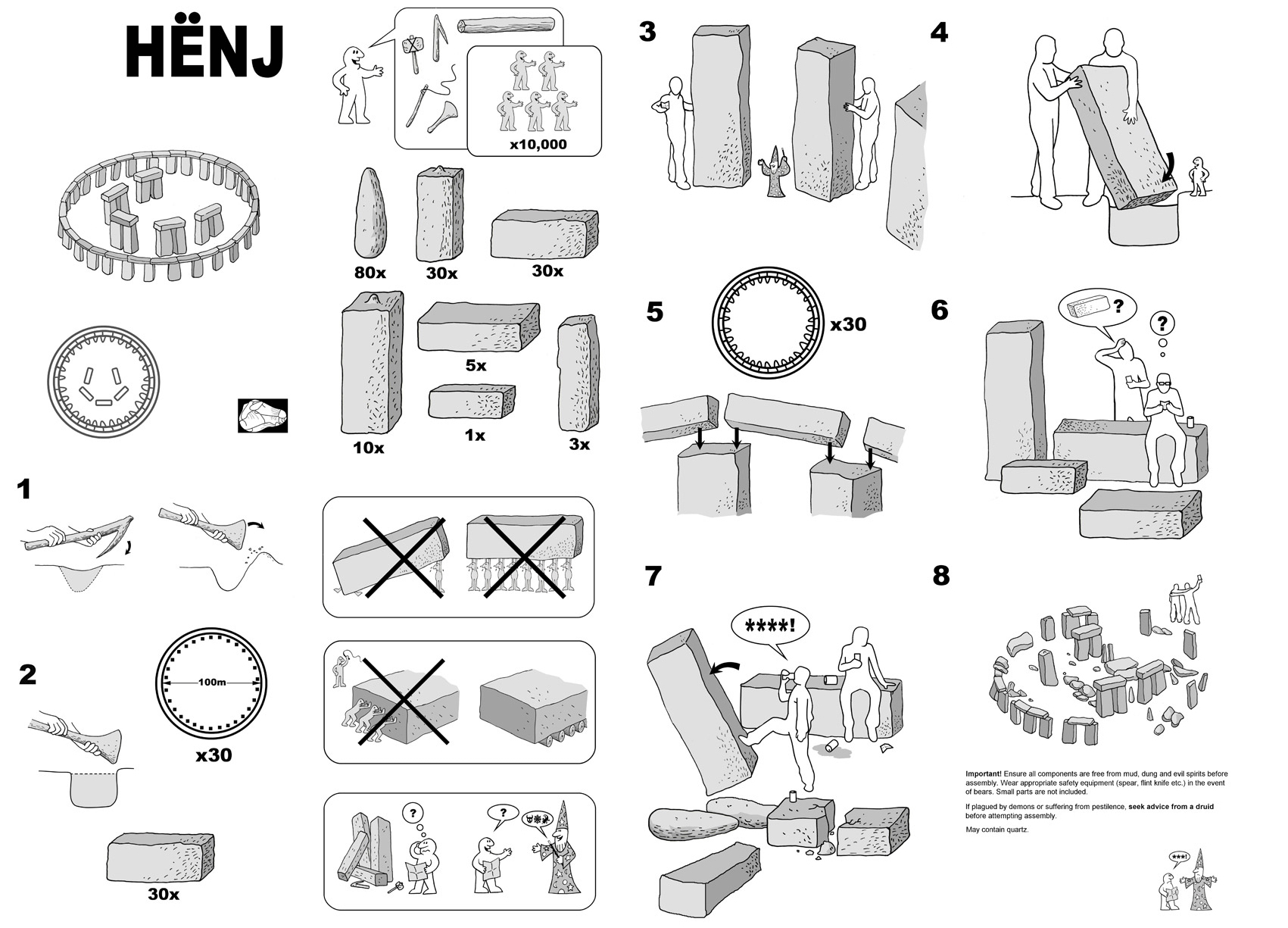

one thing a swordsmith taught me is that the myth that Japanese smiths folded the blade of a katana one thousand times, is false - it was actually folded to a thousand layers - which is around seven folds. (remember the episode about folding paper multiple times?) Question, error in translation... Folded a thousand times or a thousand folds, which would be the better translation, and we have all read those IKEA instruction manuals havnt we?.. |

|

|

|

Post by the light works on Aug 18, 2015 14:09:58 GMT

one thing a swordsmith taught me is that the myth that Japanese smiths folded the blade of a katana one thousand times, is false - it was actually folded to a thousand layers - which is around seven folds. (remember the episode about folding paper multiple times?) Question, error in translation... Folded a thousand times or a thousand folds, which would be the better translation, and we have all read those IKEA instruction manuals havnt we?.. combination of translation and hype.  |

|