|

|

Post by the light works on Mar 6, 2013 20:22:13 GMT

If I'm going to add a subpanel in my garage working off of the main breaker box: 1) How may amps should it be (30 v 60)? I'll be using it for lighting in garage & shed, garage door opener, air compressor (occasional usage), & assorted power tools. 2) Do I need to switch off the main circuit before adding the circuit for the new subpanel? 3) If I've got this right, 30A requires a three wire feed while a 60A would be a four wire feed, right? 4) Last question: For the feed from the main to the sub, romex vs armored? It will be a fully inside run from the main to the garage. Thanks! 1: for a common home garage/shop, I run 1 15A lighting circuit and 1 20A plug circuit. this will run 1 power tool at a time. however, if you are installing a subpanel; I would go ahead and go with at least 40 amps, to allow for the inevitable expansion. if there is any chance of putting in a hot tub, then go with at least 60. 2: I do not. however, you might be more comfortable doing so. if done properly, you do not come into contact with any energized components, but mistakes are possible. 3:any 120/240V combination circuit requires 4 wires (US single phase) ground MUST be separate from neutral until the original point of disconnect. 4: unless local codes require conduit, then type NM-B (romex) is acceptable as long as it is reasonably protected from physical damage. in an unfinished garage, wire run against the side of the stud is considered reasonably protected in the jurisdiction I work in - your local codes may vary. wire sizing: basic rule of thumb: #10 gets a 30 amp breaker, #8 gets 40A and #6 gets a 50A (though a furnace can be wired with #6 on a 60A breaker as long as the furnace load is less than 60A.) |

|

|

|

Post by The Urban Mythbuster on Mar 6, 2013 20:28:55 GMT

Thanks for all the help! This has been on my to do list since last year.

Since I now have to rebuild the shed (last snowfall collapsed the roof), I might as well get the electrical set at the same time. So much for a metal shed out of a kit, this time will be an overengineered wood shed that I'll build from the ground up.

|

|

|

|

Post by the light works on Mar 6, 2013 20:39:01 GMT

be aware that current codes require GFCI protection for EVERY receptacle in the garage except those used only for a specific piece of equipment - and those must not be able to have anyything else plugged into them.

|

|

|

|

Post by The Urban Mythbuster on Mar 6, 2013 20:55:53 GMT

Thanks for the heads up on that!

|

|

|

|

Post by GTCGreg on Mar 6, 2013 22:23:03 GMT

I have a number of power tools I use in the garage including a 240 volt air compressor and a 220 volt MIG welder. I put a sub-panel in the garage mainly because I was out of breaker positions on the main box and didn't want to replace it. I put a 50A, two pole (240 volt) breaker in the main panel and feed the sub-panel with that through 6ga wire.

I have one 240 volt, 30A circuit in the sub for the compressor or welder (one at a time), Two 20A circuits for outlets and one 15A circuit for lighting. If I ever get a plasma cutter attachment for the MIG, I'll have to add another 240 volt circuit for the compressor so I can have compressed air for the cutter.

My problem is that the house only has a 100 Amp entrance. I really need to upgrade it. Between the pool filtering system, A/C, electric range and power tools, I have tripped the main a couple of times. With underground wiring, they'd probably have to dig up the yard to put in a larger entrance.

Question for Lightworks:

I ran three 6ga between the main panel and sub (L1, L2, and Neutral) through 3/4" metal conduct. The neutral in the main panel is bonded to the box. The neutral in the sub panel is not bonded to the box. My question is, should I have run another 6ga just for the ground and if so, where would I connect it? I just assumed the ground through the conduct was acceptable.

|

|

|

|

Post by the light works on Mar 6, 2013 22:25:53 GMT

I have a number of power tools I use in the garage including a 240 volt air compressor and a 220 volt MIG welder. I put a sub-panel in the garage mainly because I was out of breaker positions on the main box and didn't want to replace it. I put a 50A, two pole (240 volt) breaker in the main panel and feed the sub-panel with that through 6ga wire. I have one 240 volt, 30A circuit in the sub for the compressor or welder (one at a time), Two 20A circuits for outlets and one 15A circuit for lighting. If I ever get a plasma cutter attachment for the MIG, I'll have to add another 240 volt circuit for the compressor so I can have compressed air for the cutter. My problem is that the house only has a 100 Amp entrance. I really need to upgrade it. Between the pool filtering system, A/C, electric range and power tools, I have tripped the main a couple of times. With underground wiring, they'd probably have to dig up the yard to put in a larger entrance. direct buried? if it's in conduit, they might be able to upgrade to copper and squeeze it through, depending on the conduit. |

|

|

|

Post by GTCGreg on Mar 6, 2013 22:33:29 GMT

No, it's direct burial. The may be able to use one of those Ditch-Witch boring things to get the wire from the transformer box to the house. It's only about 100 feet.

|

|

|

|

Post by the light works on Mar 6, 2013 23:05:36 GMT

better to just open the ditch and lay conduit. throw a couple extras for phone and TV upgrades, too.

direct burial does die unexpectedly at the worst possible time.

|

|

|

|

Post by silverdragon on Mar 7, 2013 7:02:03 GMT

60 amp, you will be running 8mm or 10 mm wiring....minimum.....

Its a right bar-steward, it doesnt bend well, so plan straight lines as much as possible, and it doesn't like hiding in trunking either....

I have that on my Shower circuit in the house, its a 3kw single appliance rated circuit.

I also have that on my Pond, as the pond heater is a 3kw unit. (Anti-Frost measures, keeps water from freezing, 4,000 UK gallons pond to keep above freezing...)

I am going to suggest go for the 60 amp (Or even higher) right now, whilst you are planning it, because that may be future proofing, and if you find you are needing it in the future you will regret not doing it now whilst it saves you money..... and time.....

ALWAYS oversize if you even suspect it may be needed.

Especially if you can afford it.

|

|

|

|

Post by c64 on Mar 7, 2013 13:58:12 GMT

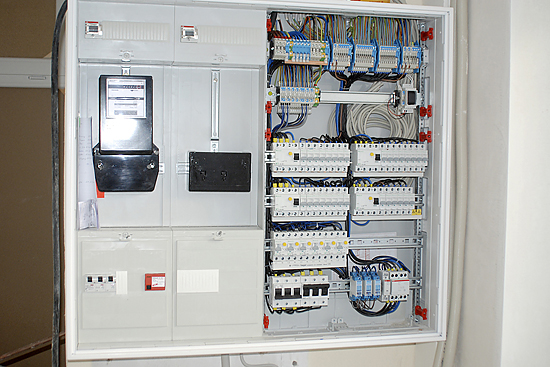

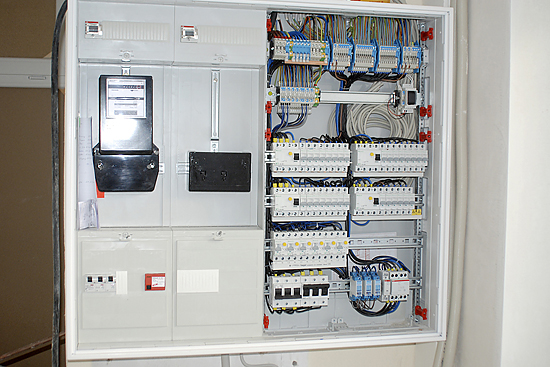

Over here, it looks like this:  On top is the underground cable coming into the building from outside. It contains L₁, L₂, L₃; NPE. The thin white cable is connected to the ground loop around the building. The bottom cable runs to the main fuse box and contains L₁, L₂, L₃; N; PE. The NPE from the transformer building is split into N (neutral) and PE (Protective Earth). In the picture is an old box, the new ones have roughly the same shape but are grey. The transparent lid isn't original. The old ones had a black lid, the new ones a grey one which is secured and you need special tools. The transparent lid was retrofitted by the utility company to prevent the urge of curious home owners to have a look inside. The new boxes require special tools to open them.  This is a standard fusebox found in 1-family houses. The outlet (with its own breaker) and the 3 screw-in plug fuses are not standard. The screw-in fuses are mostly used for extra strong (>21kW) flash heaters or to supply a secondary breaker box.  Closeup of the top connectors of the circuit breakers  And the wiring (of a larger box). Top row are just connectors between internal wiring and external wiring of the building. It's extra easy to rewire everything. Bottom row are master breakers, surge protectors and fire prevention RCD (all optional) And the rest are the circuit breakers and an individual personal protection RCDs I can't really tell what the second row is for but I assume it's the door bell transformer and wiring on the right hand side and some fancy extra complicated wiring on the left which might be a kill switch related system. |

|

|

|

Post by the light works on Mar 7, 2013 14:39:58 GMT

these aren't all the same project, but it will give you an idea of what ours look like

this is what the power company gets - their meter plugs into the socket.

|

|

|

|

Post by the light works on Mar 7, 2013 14:42:02 GMT

this is for a smallish house. breaker panel on the right, communications panel on the left.

|

|

|

|

Post by the light works on Mar 7, 2013 14:44:19 GMT

and this is for a serious house. the extra panels are the computer interface panels. (there is a second breaker panel hidden behind the doorframe, as well)

|

|

|

|

Post by c64 on Mar 7, 2013 15:04:00 GMT

And here are the old circuit breakers we had until the late 70s, they are not allowed any more for new installations for obvious reasons:  |

|

|

|

Post by the light works on Mar 7, 2013 15:19:58 GMT

our 70s circuit breakers were thermal trip, only. there were a lot of house fires caused by direct shorts. (the wire would burn through before the breaker tripped) now we have mag/thermal breakers that kick in a half cycle on a direct short.

|

|

|

|

Post by c64 on Mar 7, 2013 15:39:27 GMT

our 70s circuit breakers were thermal trip, only. there were a lot of house fires caused by direct shorts. (the wire would burn through before the breaker tripped) now we have mag/thermal breakers that kick in a half cycle on a direct short. We never had anything else. The breaker must act like a classic fuse. Those either burn out slowly from overload or "detonate" in a direct short circuit. |

|

|

|

Post by GTCGreg on Mar 7, 2013 18:13:16 GMT

On the topic of power distribution, here's an interesting power outlet I found. I installed one in our kitchen where I usually leave my cell phone to charge. The little cell phone charger somehow kept walking off so this solved the problem. It has two 15A standard outlets with two USB charging outlets built in.  |

|

|

|

Post by the light works on Mar 7, 2013 23:54:09 GMT

I'd mentioned that earlier. how is the lifespan on your USB cables? I've already had to replace a car charger and my regular cable is going wonky on me, too.

|

|

|

|

Post by GTCGreg on Mar 8, 2013 0:03:26 GMT

I'd mentioned that earlier. how is the lifespan on your USB cables? I've already had to replace a car charger and my regular cable is going wonky on me, too. I've had a couple of car charger cables go bad on me. The problem always seemed to be contact problems with where it plugs into the phone. I have an iPhone and they have that wacky Apple connector although I've never had problems with the Apple supplied cables. Like the wall-warts, most of the cables seem to disappear before they have a chance to go bad. This outlet isn't going to help with that problem unless I glue them in. |

|

|

|

Post by c64 on Mar 8, 2013 10:49:15 GMT

On the topic of power distribution, here's an interesting power outlet I found. I installed one in our kitchen where I usually leave my cell phone to charge. The little cell phone charger somehow kept walking off so this solved the problem. It has two 15A standard outlets with two USB charging outlets built in.  Nice, hidden, unpluggable wall warts wasting power 24/7! I prefer the power bars with USB charger you can unplug or switch off. Also I have a 12V Bus in my E-Lab with 12V sockets and have installed some in the kitchen, some in the living room and one for the telephone. I use them to plug in devices which need 12V or use a car USB adaptor. The bus has a battery backup from huge industrial lead acid batteries. Those batteries are meant as part of the rectifying process and to deliver extreme currents without using a huge transformer and expensive rectifiers. So I have power in battery quality and it will still work during a power outage. Also the efficiency is a lot better than using all those wall warts. And the 230V inverter built in my car can be removed and installed into the furnace room to keep the house warm even during a power outage. This should work at least 3 days with the pump set to very low. |

|