|

|

Post by c64 on Nov 30, 2015 19:28:03 GMT

If you wonder what I am currently working on:

The incident right after the excavator accident looks just like what I am working on for the past month, just a huge room full of those. Some stuff was built in in 1952!

|

|

|

|

Post by the light works on Nov 30, 2015 20:03:42 GMT

now you get it. my main breaker only has to have a 100,000 amp interrupting rating, because my transformer, which is about 250 feet away, cannot deliver more than 100,000 amps to my main breaker. they can shut off power to my main breaker by pulling the meter, or they can either cut my service drop at the pole, or pull the fuse on the transformer.

|

|

|

|

Post by GTCGreg on Nov 30, 2015 20:41:21 GMT

or pull the fuse on the transformer. Which will also cut service to anyone else that may be on that transformer. |

|

|

|

Post by the light works on Nov 30, 2015 21:03:33 GMT

or pull the fuse on the transformer. Which will also cut service to anyone else that may be on that transformer. yes, all 5 or 6 of them. they try to avoid that, but in some cases... I once caught a fault where the high voltage line was faulting to ground - charged the entire area to around a hundred volts. wasn't noticeable unless you hit something that was connected to the grounded conductor system. edit: I cot called when a plumber got bit off an outside faucet (old house with copper plumbing) |

|

|

|

Post by silverdragon on Dec 3, 2015 9:24:30 GMT

|

|

|

|

Post by silverdragon on Dec 3, 2015 9:27:38 GMT

|

|

|

|

Post by silverdragon on Dec 3, 2015 9:33:22 GMT

Ignore the awful music...

|

|

|

|

Post by silverdragon on Dec 3, 2015 9:37:00 GMT

More...nsfw language is a bit strong in some cases.

|

|

|

|

Post by wvengineer on Dec 27, 2015 13:47:15 GMT

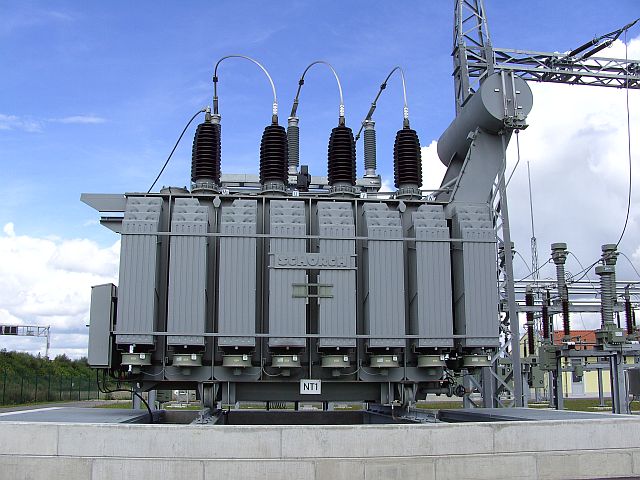

But very close to the buildings. With 230V/400V rotary current systems, the distance between transformer and building can be much greater. One of those is usually enough for medium sized village:  It looks like the transformer is on wheels. Why would you do that? |

|

|

|

Post by c64 on Dec 27, 2015 14:14:29 GMT

But very close to the buildings. With 230V/400V rotary current systems, the distance between transformer and building can be much greater. One of those is usually enough for medium sized village:  It looks like the transformer is on wheels. Why would you do that? Large transformers are always on wheels. This is the most convenient way to put them up or replace them. The height of the base with the rails is normed so you push a trailer with rails next to it and then just shove the transformer on or off. Large ones use real rails. In this picture you can see how to turn it by 90° to load and unload it on a trailer or truck.  Medium sized ones have fixed wheels  Small ones which are often installed inside buildings use shopping cart like wheels. You can push them through doors and around corners like a shopping cart and they are set on U-shaped rails. When the transformer is in place, the wheels are twisted by 90° to secure the transformer. This can easily be done using a crowbar or a large wrench.  The idea of the wheels is that there are usually overhead feeding lines where the transformers are and there is no way to use a crane without disassembling a lot of stuff. For the small ones, the idea is that you can easily handle them inside the building. Look at the picture of the carport style transformer station.How would you install this thing without wheels? |

|

|

|

Post by the light works on Dec 27, 2015 15:24:16 GMT

when we installed a larger genset for a telephone relay station we used a carpet stinger on a forklift for a gantry extension. the worst part of the operation was the boss had thought a wheelbarrow wheel without the tire would be suitable as a roller. (it crushed as soon as we lifted the genset) the best part was the rental yard gave us the use of the carpet stinger for free, as a previous user had tipped the load forward and bent the stinger when we got done, the weight of the generator had straightened it.

|

|

|

|

Post by wvengineer on Dec 27, 2015 15:50:09 GMT

Interesting way to do the install. However, I could never see something like that working over here due to earthquake codes. Any setup in an quake zone (most of the US to one degree or another) would require it to be secured down to prevent movement in a quake. Last thing you want in such a situation is a transformer tipping over or wandering off. The risk of overhead wire or structure falling is bad enough.

|

|

|

|

Post by the light works on Dec 27, 2015 16:43:36 GMT

Interesting way to do the install. However, I could never see something like that working over here due to earthquake codes. Any setup in an quake zone (most of the US to one degree or another) would require it to be secured down to prevent movement in a quake. Last thing you want in such a situation is a transformer tipping over or wandering off. The risk of overhead wire or structure falling is bad enough. part of that is that we really don't tend to have transformers in that size range. all the same, when they ARE in that size range, they seem to be rail mounted - even if there is redundant anchoring holding them in place.   again, this is what our typical distribution system transformers look like.   |

|

|

|

Post by c64 on Dec 28, 2015 13:34:08 GMT

Interesting way to do the install. However, I could never see something like that working over here due to earthquake codes. Any setup in an quake zone (most of the US to one degree or another) would require it to be secured down to prevent movement in a quake. Last thing you want in such a situation is a transformer tipping over or wandering off. The risk of overhead wire or structure falling is bad enough. The wheels are secured after installing or loading them onto a truck. Would be real bad if it could roll on the flatbed trailer while driving! Smaller transformers (usually in basement transformers) have wheels on an U-rail which are turned by 90° so the transformer can only wiggle a bit against the sides of the U-rails. Medium sized ones (Megawatt class) have fixed wheels but they are secured by bolted wedges  or as you can see in the picture a "foot" which converts the wheel into a square. Basically two wedges pushed from both sides of a wheel until the wheel rests on the wedges and a frame holding the wedges together.  Te large ones using rails are secured by clamps which are bolted to the rails. Here you can see the left rear clamp:  And here if you look closely the front right one.  They are diagonal since metal expands and contracts with temperature so the transformer has plenty of room to settle but can't roll away. There is just one problem. This is the way it is meant to be done. A special truck, extension rails which can be bolted to the truck and the base rails and adjustable heavy duty support rails.Everything is perfectly levelled and they use winches to move the transformer:  But sometimes hiring professionals with proper gear is too expensive for management. Some guys and an excavator is much cheaper...  |

|

|

|

Post by c64 on Dec 28, 2015 13:44:41 GMT

And by the way, if you look at the picture with the red truck, note the overhead wiring. In Germany, the average power out time is less than 10 minutes per year in average. The last power outage in my area was about 10 years ago and lasted for 20 minutes. Without the rails and truck, using a crane to lift the thing in place, they would have to de-energize the whole transformer station and blacking out an entire province for many days! The longest power outage I have ever witnessed was at my parents place, a small town.I can't find actual pictures on the net but it had looked like this:   The power was out for 6 hours. |

|

|

|

Post by the light works on Dec 28, 2015 15:22:12 GMT

And by the way, if you look at the picture with the red truck, note the overhead wiring. In Germany, the average power out time is less than 10 minutes per year in average. The last power outage in my area was about 10 years ago and lasted for 20 minutes. Without the rails and truck, using a crane to lift the thing in place, they would have to de-energize the whole transformer station and blacking out an entire province for many days! The longest power outage I have ever witnessed was at my parents place, a small town.I can't find actual pictures on the net but it had looked like this:   The power was out for 6 hours. I average nearly a hundred hours of power outage per year. the longest single outage I have seen was just over three days. but the lines that bring power to me span a distance roughly equivalent to the distance from hamburg to frankfurt. when a tree takes out a power line, line crews are 10-60 miles away depending on the jurisdiction and luck. I'm on the 60 mile end of the spectrum. so depending on where a tree went through the lines, and how many trees went down, the idea of having it fixed in ten minutes is a bit laughable. I've had incidents where a car took out a pole, and it took 10 minutes just to find the damaged pole. (partly due to poor information from dispatch) as far as scheduled outages, though. a lot of tarnsformer changes may take a half hour to an hour, but they only affect the houses immediately connected to them. |

|

|

|

Post by GTCGreg on Dec 28, 2015 21:20:54 GMT

Now THERE'S your problem. Someone got their head stuck in the transformer. |

|