|

|

Post by rmc on Dec 26, 2019 0:38:29 GMT

Yes and no on that, I think, thelightworks. Keep in mind that air flows through some rather complicated baffles. It doesn't just port directly to the outside, or it would bring in a lot of the unwanted noises too. Inside a typical automobile muffler we can see some of the ideas my baffle system hopes to employ. Perhaps using some of the maths with regard to back pressures and air flow for a typical muffler could be useful for deciding how much power and work must be done? lke I said - with cheap high volume blowers, the blower will drown out most of the outside noises, anyway - and especially if you are artificially restricting the airflow. all the fans I use in bathrooms are rated for quiet operation, and even with them, adding 180 degrees of bend roughly doubles the blower noise. that's why I like the oversized flex duct. there is a lot less restriction, and the soft material seems to soak up noise. it would also make it very easy to experiment with the shape of the duct. of course, the heating guys like it because it is the same stuff they use for distribution runs in their HVAC system. Just saw this particular air mover in action over at the retirement home where my dad lives. It was about the same loudness as my box fan, or a bit less surprisingly enough. In fact when I first saw it at a distance, I didn't even realize it was on, but it was! It was on the second setting too. Pretty darned quiet. Definitely not going to be any sort of sound issue. It's rated at 500 cfm, 1.5 amps. I think I'll risk going one higher than this one because I felt the air at the intake and though it was able to hold a piece of paper in place and all that, I still think a little more power is in order (engineering by the seat of my pants, or by guestimation) with regard to suction or evacuating a room of its air. Daytom 5UMP6 (air mover, carpet dryer): www.walmart.com/ip/Carpet-Floor-Dryer-120V-500-cfm-Yellow-DAYTON-5UMP6/505269638So to some small degree, I've already started some of the observational experimentation I intend to do. EDIT: Will be trying this one first : www.lowes.com/pd/BlueDri-PRO-9-in-3-Speed-Indoor-Outdoor-Air-Mover-Fan/1000793862Then if that one was almost strong enough, but just need a little bit more, will try this one next (return policy should helpful in this)... www.lowes.com/pd/XPOWER-XPOWER-P-230AT-1-4-HP-925-CFM-Multi-Purpose-Mini-Mighty-Air-Mover-Utility-Fan-Dryer-Blower-with-Build-in-Power-Outlets-and-Timer/1001359566Two reviewers declared that they used it as a fan for cooling themselves while they slept. Stated that it's very quiet. |

|

|

|

Post by the light works on Dec 26, 2019 5:19:19 GMT

lke I said - with cheap high volume blowers, the blower will drown out most of the outside noises, anyway - and especially if you are artificially restricting the airflow. all the fans I use in bathrooms are rated for quiet operation, and even with them, adding 180 degrees of bend roughly doubles the blower noise. that's why I like the oversized flex duct. there is a lot less restriction, and the soft material seems to soak up noise. it would also make it very easy to experiment with the shape of the duct. of course, the heating guys like it because it is the same stuff they use for distribution runs in their HVAC system. Just saw this particular air mover in action over at the retirement home where my dad lives. It was about the same loudness as my box fan, or a bit less surprisingly enough. In fact when I first saw it at a distance, I didn't even realize it was on, but it was! It was on the second setting too. Pretty darned quiet. Definitely not going to be any sort of sound issue. It's rated at 500 cfm, 1.5 amps. I think I'll risk going one higher than this one because I felt the air at the intake and though it was able to hold a piece of paper in place and all that, I still think a little more power is in order (engineering by the seat of my pants, or by guestimation) with regard to suction or evacuating a room of its air. Daytom 5UMP6 (air mover, carpet dryer): www.walmart.com/ip/Carpet-Floor-Dryer-120V-500-cfm-Yellow-DAYTON-5UMP6/505269638So to some small degree, I've already started some of the observational experimentation I intend to do. EDIT: Will be trying this one first : www.lowes.com/pd/BlueDri-PRO-9-in-3-Speed-Indoor-Outdoor-Air-Mover-Fan/1000793862Then if that one was almost strong enough, but just need a little bit more, will try this one next (return policy should helpful in this)... www.lowes.com/pd/XPOWER-XPOWER-P-230AT-1-4-HP-925-CFM-Multi-Purpose-Mini-Mighty-Air-Mover-Utility-Fan-Dryer-Blower-with-Build-in-Power-Outlets-and-Timer/1001359566Two reviewers declared that they used it as a fan for cooling themselves while they slept. Stated that it's very quiet. maybe you and I have different definitions of a quiet fan. for my part, when Mrs TLW is visiting someone else, the first thing I do is shut off the fan and dehumidifier she runs in the bedroom, so I can actually have a quiet bedroom to sleep in and don't have to hide under the covers to get away from the cold draft. I also did the math, and if you made your chamber 8X5X5, which seems to me like a reasonable size to prevent banging the walls when you shift sleeping positions; that's 200 cubic feet. means a 500 CFM fan would be changing the air every 25 seconds. |

|

|

|

Post by rmc on Dec 26, 2019 11:47:10 GMT

Just saw this particular air mover in action over at the retirement home where my dad lives. It was about the same loudness as my box fan, or a bit less surprisingly enough. In fact when I first saw it at a distance, I didn't even realize it was on, but it was! It was on the second setting too. Pretty darned quiet. Definitely not going to be any sort of sound issue. It's rated at 500 cfm, 1.5 amps. I think I'll risk going one higher than this one because I felt the air at the intake and though it was able to hold a piece of paper in place and all that, I still think a little more power is in order (engineering by the seat of my pants, or by guestimation) with regard to suction or evacuating a room of its air. Daytom 5UMP6 (air mover, carpet dryer): www.walmart.com/ip/Carpet-Floor-Dryer-120V-500-cfm-Yellow-DAYTON-5UMP6/505269638So to some small degree, I've already started some of the observational experimentation I intend to do. EDIT: Will be trying this one first : www.lowes.com/pd/BlueDri-PRO-9-in-3-Speed-Indoor-Outdoor-Air-Mover-Fan/1000793862Then if that one was almost strong enough, but just need a little bit more, will try this one next (return policy should helpful in this)... www.lowes.com/pd/XPOWER-XPOWER-P-230AT-1-4-HP-925-CFM-Multi-Purpose-Mini-Mighty-Air-Mover-Utility-Fan-Dryer-Blower-with-Build-in-Power-Outlets-and-Timer/1001359566Two reviewers declared that they used it as a fan for cooling themselves while they slept. Stated that it's very quiet. maybe you and I have different definitions of a quiet fan. for my part, when Mrs TLW is visiting someone else, the first thing I do is shut off the fan and dehumidifier she runs in the bedroom, so I can actually have a quiet bedroom to sleep in and don't have to hide under the covers to get away from the cold draft. I also did the math, and if you made your chamber 8X5X5, which seems to me like a reasonable size to prevent banging the walls when you shift sleeping positions; that's 200 cubic feet. means a 500 CFM fan would be changing the air every 25 seconds. I've had to learn to sleep with the fan running, unfortunately. The person above me has apparently chosen to punish me for having an earlier sleep schedule than she has. Anyway, she switches from barefoot, rumble-stomping (almost tolerable with the fan on) to some sort of hard soled shoe after 10pm. And continues that nonsense until after midnight sometimes. The fan was only able to damp down barefoot "walking". I think it must have been me waking before sunrise during the summer to make certain my mom could get her 20 minute walk in before the heat of the day and a lot of unneeded sun exposure. So about by September the person upstairs seems to have sought to keep me up later to ensure I don't do any of that anymore. All speculation. Many here feel that the person upstairs couldn't hear me simply stirring around, merely getting ready to go out for a walk. Who knows. I need more than a fan at this point, though. To your point about moving air. It's likely a bit more complicated than that once you include baffles, and other convoluted pathways to damp outside noise from getting in. After all, there is much discussion about the power reduction in air flow when there is merely a 90 degree turn involved. I have 180 degree turns. That means the air mass switches direction. A lot of power is required for that. I have an inlet beneath the body of the bed. Air circulates up and around the contours of the bed and sheets in order to reach the upper cabin, me, and then the outlet port where the motor and fan are located... fan is mounted to the outside of the cabin. It's a lot more work for the air mass. I think baffles for automobile mufflers are designed with much of that considered. There is likely maths specifically suited to figuring out what sort of power loss is involved pushing air through sound-damping baffles and other tight spaces. The following linked paper discusses the maths involved for damping waveform energy within an automobile muffler. It's not exactly what I am after with regard to air mass momentum, but the paper does show some level of engineering with regard to eliminating a lot of sound. www.comsol.com/paper/download/297661/prasad_paper.pdf |

|

|

|

Post by rmc on Dec 26, 2019 13:17:44 GMT

|

|

|

|

Post by the light works on Dec 26, 2019 15:03:09 GMT

keep in mind that an automotive muffler is designed to reduce the sound that is inherent in the airflow going through it. it is taking a pulsed airflow and dampening the pulses with the intention of converting it to a smooth flow. what you are doing is taking a smooth airflow, and choking it. what this is going to do is put back pressure on a blower that is not designed to cope with back pressure; and it will result in a lot more blower noise, and slowing the drive motor below its optimum speed - which will make it run hot, inefficiently, and loud.

what you want is a duct that minimizes the intrusion of noise from outside the duct, while allowing a slow turning fan to carry sufficient air to ventilate your isolation chamber sufficiently to prevent it from becoming stuffy inside.

|

|

|

|

Post by GTCGreg on Dec 26, 2019 16:08:14 GMT

keep in mind that an automotive muffler is designed to reduce the sound that is inherent in the airflow going through it. it is taking a pulsed airflow and dampening the pulses with the intention of converting it to a smooth flow. what you are doing is taking a smooth airflow, and choking it. what this is going to do is put back pressure on a blower that is not designed to cope with back pressure; and it will result in a lot more blower noise, and slowing the drive motor below its optimum speed - which will make it run hot, inefficiently, and loud. what you want is a duct that minimizes the intrusion of noise from outside the duct, while allowing a slow turning fan to carry sufficient air to ventilate your isolation chamber sufficiently to prevent it from becoming stuffy inside. Most centrifugal blowers will draw less power with restricted airflow. Fans on the other hand, usually will draw more power and thus run harder with restricted airflow. The dual cage blowers we use in ambulances draw about 20 A if you just operate them in open air on the bench. When the same blowers are put inside the enclosures where the airflow is restricted, they draw about 15 A. |

|

|

|

Post by the light works on Dec 26, 2019 17:28:21 GMT

keep in mind that an automotive muffler is designed to reduce the sound that is inherent in the airflow going through it. it is taking a pulsed airflow and dampening the pulses with the intention of converting it to a smooth flow. what you are doing is taking a smooth airflow, and choking it. what this is going to do is put back pressure on a blower that is not designed to cope with back pressure; and it will result in a lot more blower noise, and slowing the drive motor below its optimum speed - which will make it run hot, inefficiently, and loud. what you want is a duct that minimizes the intrusion of noise from outside the duct, while allowing a slow turning fan to carry sufficient air to ventilate your isolation chamber sufficiently to prevent it from becoming stuffy inside. Most centrifugal blowers will draw less power with restricted airflow. Fans on the other hand, usually will draw more power and thus run harder with restricted airflow. The dual cage blowers we use in ambulances draw about 20 A if you just operate them in open air on the bench. When the same blowers are put inside the enclosures where the airflow is restricted, they draw about 15 A. there has to be something else going on there. you can't make an electric motor draw less power by adding drag. the centrifugal blowers must operate more efficiently inside the shrouds. - perhaps because the shroud allows it to create a low pressure zone in the inlet, which creates less resistance. |

|

|

|

Post by GTCGreg on Dec 26, 2019 17:50:14 GMT

Most centrifugal blowers will draw less power with restricted airflow. Fans on the other hand, usually will draw more power and thus run harder with restricted airflow. The dual cage blowers we use in ambulances draw about 20 A if you just operate them in open air on the bench. When the same blowers are put inside the enclosures where the airflow is restricted, they draw about 15 A. there has to be something else going on there. you can't make an electric motor draw less power by adding drag. the centrifugal blowers must operate more efficiently inside the shrouds. - perhaps because the shroud allows it to create a low pressure zone in the inlet, which creates less resistance. What is happening in the case of a blower is if the air cannot escape or fresh air is not drawn in, the air that already is in the area surrounding the wheel starts to spin in the same direction as the wheel and that reduces the load on the wheel. You can notice this effect using an ordinary shop vac. if you block either the intake or discharge while the vacuum is operating, you will hear the motor speed up. The reason it speeds up is because there is less load on it. |

|

|

|

Post by the light works on Dec 26, 2019 18:13:44 GMT

there has to be something else going on there. you can't make an electric motor draw less power by adding drag. the centrifugal blowers must operate more efficiently inside the shrouds. - perhaps because the shroud allows it to create a low pressure zone in the inlet, which creates less resistance. What is happening in the case of a blower is if the air cannot escape or fresh air is not drawn in, the air that already is in the area surrounding the wheel starts to spin in the same direction as the wheel and that reduces the load on the wheel. You can notice this effect using an ordinary shop vac. if you block either the intake or discharge while the vacuum is operating, you will hear the motor speed up. The reason it speeds up is because there is less load on it. I hear them accelerate when the inlet is blocked - I haven't checked with the exhaust blocked. but I do notice they get louder with the inlet obstructed. addendum: and I notice bath fans get louder with the exhaust obstructed. - both more motor noise and more air noise. |

|

|

|

Post by rmc on Dec 26, 2019 22:49:02 GMT

So now that we are talking strained fan motors, I am planning on grabbing the biggest air mover I can get away with, trying to be mindful of cost and noise. If it's too much noise I'll just return it and go one lighter.

The baffles I am making are only sort of like an automobile muffler. Essentially, it's a cabinet wide enough for the air mover. In fact it's at least twice the size needed for the air mover. Then the space is divided such that there are then two channels, or ducts. One for the air mover, the other is the rest of the turned around air passage. It's a box wide enough to have two air passages. There will be a lot of room around the air intake. The blower side will be sealed separate from that. box is lined with mineral wool acustic ceiling tile and felt for damping.

|

|

|

|

Post by the light works on Dec 26, 2019 23:08:46 GMT

So now that we are talking strained fan motors, I am planning on grabbing the biggest air mover I can get away with, trying to be mindful of cost and noise. If it's too much noise I'll just return it and go one lighter. The baffles I am making are only sort of like an automobile muffler. Essentially, it's a cabinet wide enough for the air mover. In fact it's at least twice the size needed for the air mover. Then the space is divided such that there are then two channels, or ducts. One for the air mover, the other is the rest of the turned around air passage. It's a box wide enough to have two air passages. There will be a lot of room around the air intake. The blower side will be sealed separate from that. box is lined with mineral wool acustic ceiling tile and felt for damping. the previous handyman at my church vented the restrooms by making a negative pressure duct and feeding a furnace sized squirrel cage fan with it. worked great until the fact he got it used and cheap caught up with it. I ended up replacing it with an axial inline fan and sealing off the extra space on the outlet duct. it ventilates fine, but the fan does resonate in the oversized plenum. it's only an 80 CFM fan, so the sound doesn't go much past the restrooms, and its not extremely intrusive anyway - but it's one more noise factor. again - that's why I recommend a ventilation fan with furnace flex duct instead of a rigid assembly. if you have a quiet air source, all you have to do is keep outside noise from breaching the ducting - and the flex duct will probably exclude the outside noise better than anything rigid - AND is already approved for air handling. |

|

|

|

Post by rmc on Dec 26, 2019 23:25:31 GMT

So now that we are talking strained fan motors, I am planning on grabbing the biggest air mover I can get away with, trying to be mindful of cost and noise. If it's too much noise I'll just return it and go one lighter. The baffles I am making are only sort of like an automobile muffler. Essentially, it's a cabinet wide enough for the air mover. In fact it's at least twice the size needed for the air mover. Then the space is divided such that there are then two channels, or ducts. One for the air mover, the other is the rest of the turned around air passage. It's a box wide enough to have two air passages. There will be a lot of room around the air intake. The blower side will be sealed separate from that. box is lined with mineral wool acustic ceiling tile and felt for damping. the previous handyman at my church vented the restrooms by making a negative pressure duct and feeding a furnace sized squirrel cage fan with it. worked great until the fact he got it used and cheap caught up with it. I ended up replacing it with an axial inline fan and sealing off the extra space on the outlet duct. it ventilates fine, but the fan does resonate in the oversized plenum. it's only an 80 CFM fan, so the sound doesn't go much past the restrooms, and its not extremely intrusive anyway - but it's one more noise factor. again - that's why I recommend a ventilation fan with furnace flex duct instead of a rigid assembly. if you have a quiet air source, all you have to do is keep outside noise from breaching the ducting - and the flex duct will probably exclude the outside noise better than anything rigid - AND is already approved for air handling. I think one could easily talk at normal levels and the sound would get through flexible HVAC hosing (the sound of the voice passing directly through the skin of the hose wall) After putting a lot into the walls of the chamber, I don't want weak points, making the heavy expensive sound-resistant walls all around the rest of the cabinet pointless. |

|

|

|

Post by the light works on Dec 27, 2019 0:23:19 GMT

the previous handyman at my church vented the restrooms by making a negative pressure duct and feeding a furnace sized squirrel cage fan with it. worked great until the fact he got it used and cheap caught up with it. I ended up replacing it with an axial inline fan and sealing off the extra space on the outlet duct. it ventilates fine, but the fan does resonate in the oversized plenum. it's only an 80 CFM fan, so the sound doesn't go much past the restrooms, and its not extremely intrusive anyway - but it's one more noise factor. again - that's why I recommend a ventilation fan with furnace flex duct instead of a rigid assembly. if you have a quiet air source, all you have to do is keep outside noise from breaching the ducting - and the flex duct will probably exclude the outside noise better than anything rigid - AND is already approved for air handling. I think one could easily talk at normal levels and the sound would get through flexible HVAC hosing (the sound of the voice passing directly through the skin of the hose wall) After putting a lot into the walls of the chamber, I don't want weak points, making the heavy expensive sound-resistant walls all around the rest of the cabinet pointless. if that turns out to be the case, you could always build an enclosure around the flex duct. |

|

|

|

Post by rmc on Dec 27, 2019 0:40:24 GMT

I think one could easily talk at normal levels and the sound would get through flexible HVAC hosing (the sound of the voice passing directly through the skin of the hose wall) After putting a lot into the walls of the chamber, I don't want weak points, making the heavy expensive sound-resistant walls all around the rest of the cabinet pointless. if that turns out to be the case, you could always build an enclosure around the flex duct. Okay. You win, The Last Word The Light Works. |

|

|

|

Post by GTCGreg on Dec 27, 2019 0:44:35 GMT

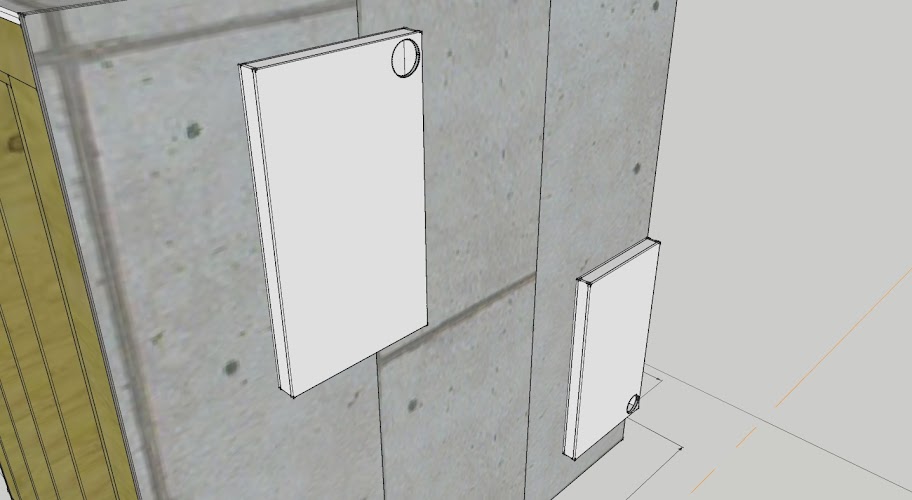

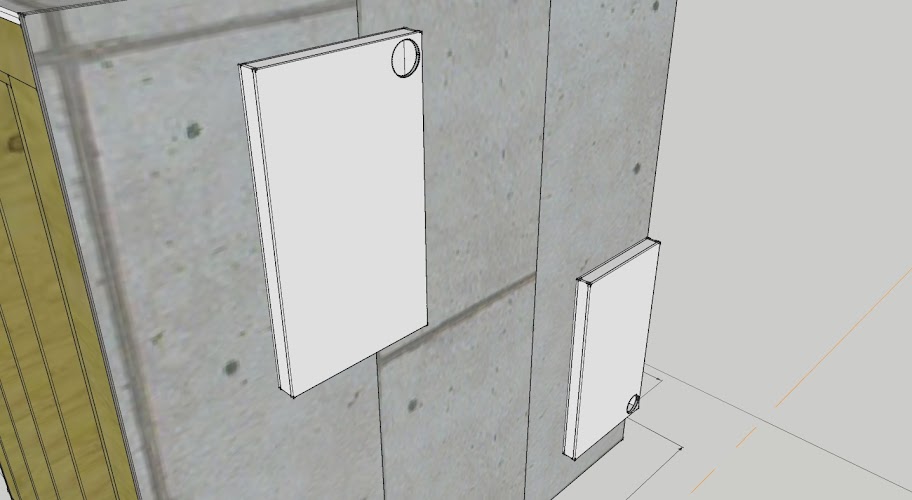

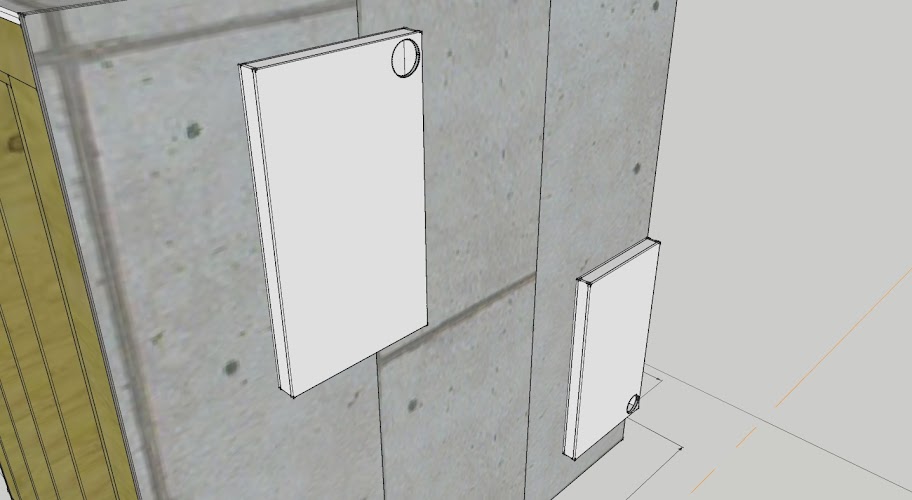

Recording studios often use sound isolation booths to record vocals. The idea is to have a small booth that blocks outside sound. For ventilation, they use two sound baffle boxes mounted on the side of the booth. A remotely located fan blows air into one baffle box while the other baffle box is used for discharge air. The entire inside of the baffle box including the baffle boards are lined with sound absorbing acoustic foam. The reason for remote mounting the fan is because they don't want any sound entering the isolation booth including from the fan motor. I've even seen some where they had a small free standing air conditioner connected to the inlet baffle box via a flexible air duct. If you don't care about fan noise, you could mount the fan or blower directly to the baffle box.  Free Standing Air Conditioner Free Standing Air Conditioner  |

|

|

|

Post by the light works on Dec 27, 2019 0:44:48 GMT

if that turns out to be the case, you could always build an enclosure around the flex duct. Okay. You win, The Last Word The Light Works. it just appears to me you are trying to swat a fly on a window with a buick. and I do have a couple years of experience with ventilation fans. |

|

|

|

Post by the light works on Dec 27, 2019 0:52:10 GMT

|

|

|

|

Post by rmc on Dec 27, 2019 2:15:22 GMT

Okay. You win, The Last Word The Light Works. it just appears to me you are trying to swat a fly on a window with a buick. and I do have a couple years of experience with ventilation fans. Using the silicone putty ear plugs and a fan on medium prevents a lot of the hard-soled shoe noise from getting through to me. Trouble is I still hear it - short of a sound-resistant sleep chamber. If I had no idea what the person upstairs was up to (with regard to her intentionally trying to annoy me) I'd be able to sleep through it using a fan and the plugs. But now, even a hint of that clack, clack clack after being asleep for an hour puts me into a bad mindset. (Still highly wired from previous benzo use) If the plugs and fan would get rid of it all, I'd be fine. At this point, though, I mustn't hear so much as a bump. So, yes, I am trying the impossible : totally mask away every frequency from someone directly above me. What I will be employing to this end is absolute overkill. |

|

|

|

Post by rmc on Dec 27, 2019 11:20:36 GMT

Recording studios often use sound isolation booths to record vocals. The idea is to have a small booth that blocks outside sound. For ventilation, they use two sound baffle boxes mounted on the side of the booth. A remotely located fan blows air into one baffle box while the other baffle box is used for discharge air. The entire inside of the baffle box including the baffle boards are lined with sound absorbing acoustic foam. The reason for remote mounting the fan is because they don't want any sound entering the isolation booth including from the fan motor. I've even seen some where they had a small free standing air conditioner connected to the inlet baffle box via a flexible air duct. If you don't care about fan noise, you could mount the fan or blower directly to the baffle box.  Free Standing Air Conditioner Free Standing Air Conditioner  Right! The baffles I am making are a lot like those. The baffle boxes are the last build. So the air mover and the boxes are the things I'll experiment with to get right. Meaning I could rebuild them if needed and return an air mover for a more appropriate one, if needed. I could spend a great deal of time playing with maths and reading papers. But this last step I'll just use trial and error since the build for that particular part is fairly small compared to the rest and since I can return air movers if needed. |

|

|

|

Post by rmc on Dec 27, 2019 17:19:31 GMT

What you want to use is a small centrifugal blower (squirrel cage type.) They are not only quieter than a fan, but can deliver substantially more static pressure as is required in a ducted application. Not only do they develop more static pressure on the discharge, but they can generate more suction on the intake. This could be used as an advantage as the blower could be mounted at the discharge end of the duct, further away from the sleep chamber and thus reducing the noise in the sleep chamber. Keep in mind that the input of a centrifugal blower is usually at right angles to its discharge. This could actually be an advantage if you design your duct work to accommodate it.  I'll start with the inexpensive Soleaire Super Fan at 800 cfm. Any idea if hooking up (taping) duct work to the inlets to achieve the desired negative pressure will work? |

|